GMRACK

The GMRack is the industrial version of the most popular laboratory gas mixer/diluter Aiolos III.

Designed and manufactured by Alytech, this version of GasMix addresses to the applications outside of the laboratory .

Compatible with the standard 19“ rack mount, this system accommodates up to 6 gas channels to make calibration gas mixtures directly at the production site or within the analyzer tower.

Using GasMix ™ GMRACK you benefit of :

- 19″ rack mounted industrial version of GasMix™

- On-board computer and a touch screen for easier control on site

- Up to 6 gas channels

- Can be remotely driven by Ethernet communication

- USB port on front panel to upload projects

- Compliance with ISO 6145-7

OPERATION

APPLICATION

TECHNICAL SPECIFICATION

OPTIONS

DOWNLOAD

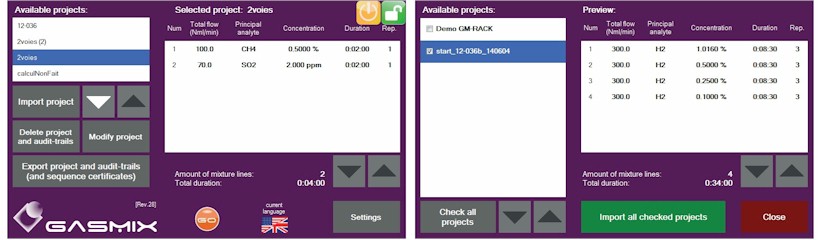

For easier use directly on site, the GMRack is equipped with on-board computer and a touch screen. Embedded GasMix™ software controls the mixer operation. It may drive an external injection valve and/or the Start command of an analyzer. The operator can do a single injection or run fully automated pre-programmed sequences for a linearity check or a multi-point calibration. A strong benefit of the GasMix™ is the drastic reduction of operator time.

GMRack is suitable for all types of instruments like gas chromatographs, microGC, gas analyzers, trace sulfur analyzer, FTIR, etc.

GMRack creates in situ controlled gas concentrations for analyzer validation, calibration or linearisation check.

- Environmental – Calibration of analyzers for ambient air surveillance, in laboratories and on site

- Manufacturing – Test bench for gas sensors quality control, LOD-LOQ and linearity checks

- Biofuels – Calibration of biofuel characterization analyzers

- Automotive Industry – Engine bench and Emission Control

- Research – Generation of complex gas mixtures

General

Number of gas channels: 2 to 6

Inlet Gas Pressure: 3 bar(g) nominal, max 8 bar(g)

Outlet Pressure: atmospheric, higher on request

Connections: Swagelok 1/8”, other on request

Gas compatibility: pure gases, concentrated gas mixtures, most aggressive gases (for specifics, contact us)

Performance characteristics

Mixing: mixing up to 6 channels simultaneously

Dilution ratio: up to 1:10000

Flow accuracy: ±1% of the setpoint

Flow repeatability: <0.1% of the setpoint

Response time to the setpoint: <5 sec

Operating Modes

Build-in computer with touch screen panel 5’’

Software: Embedded software + standard GasMix™ PC software provided

On-site upload/download projects via USB port

Can be remotely controlled via Ethernet link

I/O relay or TTL communication with an external analyzer

Other communications options and customizations available

Other

Operation temperature: 10 – 50°C

Power supply: 90-260Vac, 1,5-4A, 50-60Hz

Dimensions : L x l x h: 48.3×34.5×18 cm (19×13.6×7 inches)

Weight: approx. 9 kg (depends on configuration)

A fully inert version compatible with most aggressive gases and active compounds like sulfurs gases, NO, ammonia, VOC

Heated gas lines: Model is fitted with a heated tubings for specific applications

FReD: FReD is optional automated flow regulator to be placed downstream to the diluter. The output flow rate can be set and accurately controlled directly by GasMix™ software.

Customized versions are available, please contact us