GASMIX™ PLATFORM

Gas Mixer and Gas Diluter for Precise Gas Blending and Calibration - Aiolos III

Dynamic Gas Mixer & Gas Diluter, 2 to 6 channels, ISO 6145-7 compliant

AlySoft™ software — unified control, sequences, analyzer sync and full Audit Trail for your gas mixing system.

Aiolos III is a high-precision GasMix™ gas mixer and gas diluter. It belongs to the GasMix™ family of automated gas mixing systems used worldwide for generating calibration gas standards directly in the laboratory.

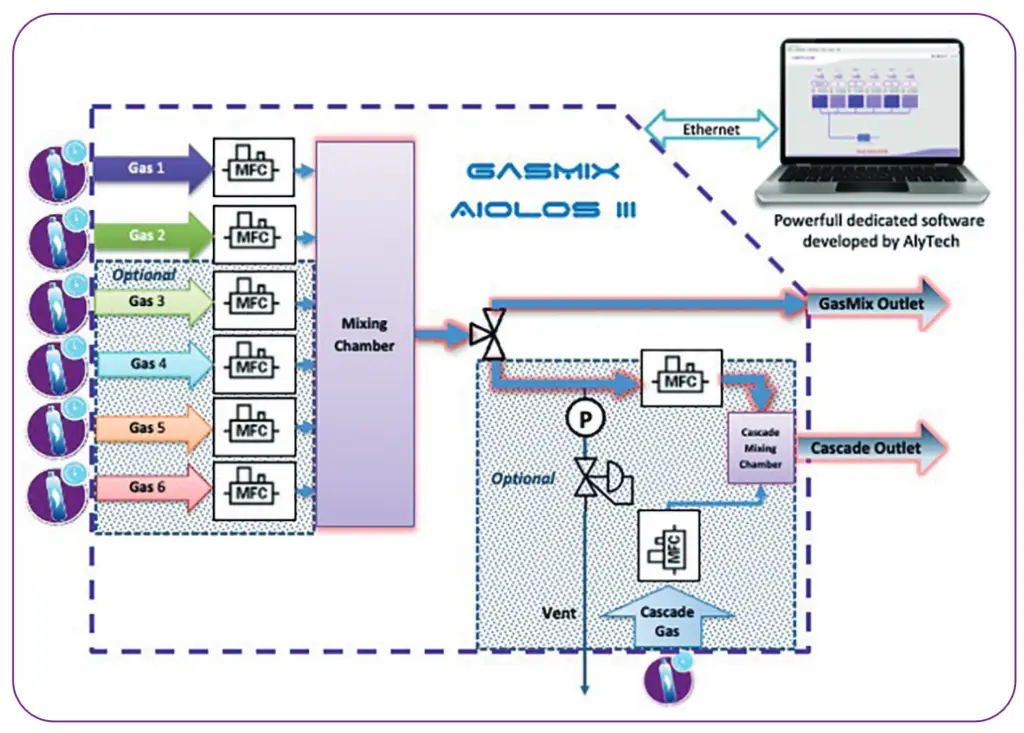

System Concept

AIOLOS III is the third-generation GasMix™ dynamic gas mixer, gas diluter and gas blending system from AlyTech, designed by engineers & chemists to generate calibration gas standards directly on site — from percent down to trace levels. By mixing and/or diluting two to six gases, Aiolos III delivers precise, reproducible concentrations with full traceability and certified metrological accuracy.

Developed and manufactured in France, the instrument builds on 20+ years of GasMix™ experience in laboratory and industrial gas preparation. As a result, this gas mixing system can act as a central gas blender for complex multi-analyzer benches, supporting multi-point calibration, linearity checks, LOD/LOQ validation, research studies and more.

Compact and robust, and compliant with ISO 6145-7, Aiolos III ensures dependable performance for laboratories that demand accuracy, flexibility and long-term reliability from their gas mixer and gas diluter.

Operation & Software for Gas Mixing Systems

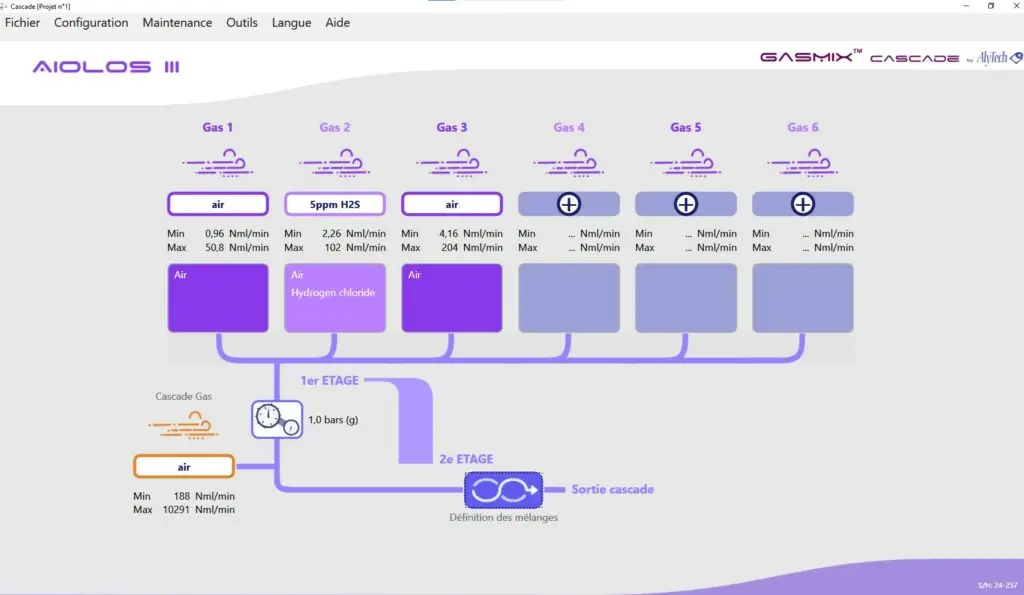

Aiolos III is operated via dedicated GasMix™ software, providing unified control of channels, flow parameters and sequences through an intuitive interface. The platform performs all calculations — mixture ratios, dilution curves and documentation — and synchronizes with external analyzers for fully automated routines on your gas mixer and gas diluter.

Programmable sequences for dilution, injection and flushing

Analyzer synchronization for automated calibration

Multi-point calibration and validation

Event logging and Audit Trail for complete traceability

Options: Injection Valve, FReD flow regulator, 2nd stage dilution mode (Cascade), Multiplexer...

High-Accuracy Gas Mixing and Metrological Excellence

Every integrated Mass Flow Controller (MFC) undergoes 400-point factory calibration across the full dynamic range and for each selected gas matrix (He, Ar, CH4, H2, N2, Air, …). This ensures superior linearity and precision, especially at very low and very high flow rates.

NIST-traceable calibration

±1% set point accuracy and <0.1% repeatability *

Automatic K-factor calculation & correction

Dilution factor: 104 in standard — up to 108 with Cascade

Automatic uncertainty calculation, full QA/QC traceability with Audit Trail

Certificate issuance with concentrations & uncertainties

* When MFCs operate between 10% and 100% of full-scale flow.

Key Benefits of the Aiolos III Gas Blender

Dynamic Mixing

Flexible generation of standards from 2 to 6 gas channels in one gas mixing system.

High Accuracy

400-point MFC calibration curves applied per gas matrix for reliable gas dilution.

Full Automation

Sequences plus analyzer sync minimize operator bench time and reduce gas consumption.

Traceable by Design

Generate certificates, uncertainty reports and full Audit Trail logging for every gas blend.

ISO 6145-7

Proven compliance for calibration and validation routines in regulated environments.

Customizable

Options: injection valve, FReD flow regulator, heated lines, multiplexer and more.

Applications: From Environmental Analysis to Petrochemical Gas Mixing

Aiolos III supports environmental monitoring, chemical/O&G, research labs and specialty gases — enabling multi-point calibration, linearity checks, LOD/LOQ validation and more with a single automated gas mixing system.

Environmental Monitoring

Calibration of ambient air analyzers with multi-point validation of NOx, SO₂, CO, and CO₂ performed using a single gas blender.

Chemical, Oil & Gas

Calibration of GC, µGC, RGA/NGA, elemental, LPG analyzers and spectrometers with flexible gas mixing systems.

Research & Academia

Custom mixtures for method development; linearity, LOD/LOQ and hysteresis testing using programmable gas blenders.

Specialty Gases & Food

Secondary standards and VOC/aroma analysis; inert version of the gas mixer for aggressive gases.

FAQ — AIOLOS III Gas Mixer & Gas Diluter

Most asked questions about multi-line GasMix™ calibration, automation and metrology for gas mixing systems and gas blenders.

Aiolos III is a multi-channel GasMix™ gas mixing system. As a gas mixer and gas diluter, it blends and dilutes several certified gases with a diluent gas to generate calibration mixtures for GC/µGC, process analyzers, CEMS and R&D applications.

Aiolos III can handle from 2 to 6 Mass Flow Controllers. The number of channels will mainly depend on the application requirements.

Thanks to dynamic dilution and multiple MFCs, Aiolos III can cover a very wide concentration range, from percent levels down to trace levels. In standard configuration Aiolos III can dilute up to 104, and up to 108 in cascade mode.

Zephyr is a compact two-gas mixer/diluter, ideal when only one standard gas and a diluent are required. Aiolos III can have up to 6 channels and is customizable with many different options (cascade, FReD, heated lines, multiplexer, etc.). Nomad focuses on mobile, field-ready GasMix™ applications, whereas Aiolos III is optimized for laboratory or fixed installations.

Aiolos III is controlled by AlySoft software, which is run via an external PC. The software allows you to build methods, Smart Sequences, log all events and export full reports for QA/QC and audits.

Yes. Aiolos III is designed for high-accuracy calibration and can support multi-point linearity checks, QAL3 routines and periodic calibrations in line with EN 14181 and similar requirements, when paired with appropriate certified gases.

Aiolos III is compatible with pure gases, mixtures and many aggressive gases such as H2S, NH3, HF, NOx, VOC and more.

Each MFC is factory-calibrated and characterized across its entire flow range. Flow accuracy is typically better than 1% of the requested value and repeatability is better than 0.1%. Combined with ISO 6145-based dilution and uncertainty calculation within the software, Aiolos III offers high accuracy and full traceability from parent cylinder certificate to final mixture.

Yes. Aiolos III can synchronize with analyzers via digital signals (such as dry contacts/TTL or Modbus, depending on configuration) and can be integrated in automated test benches. GasMix™ software allows remote control, method scheduling and data export.

Thanks to its robust design, the Aiolos III is virtually maintenance-free. We simply recommend a performance verification of the MFCs every 24 months to prevent any drift and ensure continuous compliance with ISO 6145-7 standards.

From percent levels down to ppb traces, the Aiolos III is the system of choice for ISO 14687-2 compliant calibration. It is already deployed in H2 labs to monitor critical impurities, guaranteeing the high-purity hydrogen required for fuel cell applications. See more in our application note section.

Ready to Mix It Right with AIOLOS III?

Bring traceable, automated gas calibration to your bench — powered by GasMix™ gas mixing systems.