LPG ANALYSIS

AURA II

Standalone LPG Vaporizer — safe, repeatable, analyzer-ready

LPG vaporization — Make sure there is no discrimination.

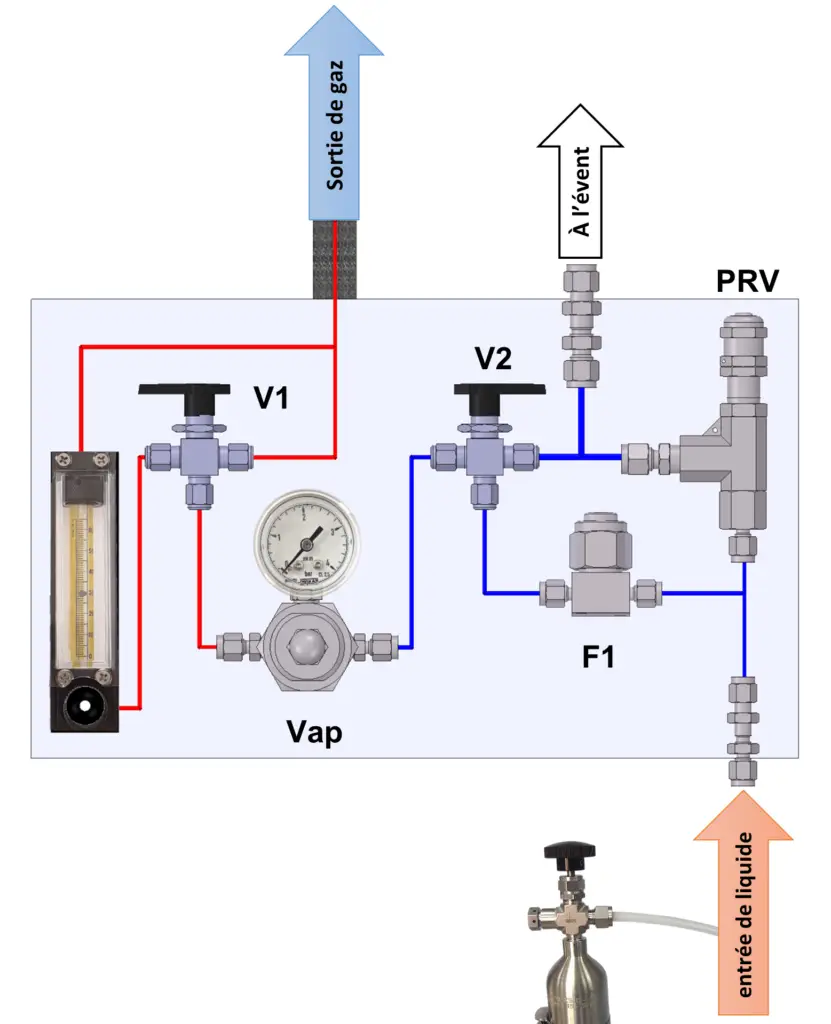

System Concept

AURA II is AlyTech’s bench-mounted vaporizer engineered for the safe and repeatable vaporization of LPG and other liquefied gases. It converts liquefied samples into a stable, contamination-free gas phase for precise analysis on GC, microGC, GC/MS, or elemental analyzers.

Paired with GasMix™ Aiolos, AURA II enables automated injection of gas and LPG samples and multi-point calibration from a single standard cylinder — improving reproducibility while saving time and consumables.

All post-vaporizer lines are heated to the point of delivery to prevent re-condensation and ensure 100% gas-phase transfer. Low-pressure operation and an inlet relief valve maximize operator safety.

Operation & Software

AURA II combines regulated heating with pressure and flow control to deliver a clean, stable gas phase.

Automated gas/LPG injections and multi-point calibration sequences

Regulated outlet: 1–3 bar abs (up to 4 bar), 20–200 cc/min

Heated transfer lines and switching valves for pressure/flow regulation

Safety: low-pressure operation and inlet relief valve

Analyzer sync (GC, microGC, GC/MS, elemental analyzers)

Metrological Excellence

Designed for traceable performance and certified reproducibility, AURA II maintains stable operating conditions and minimizes adsorption to ensure accurate quantification at trace levels. When used with Aiolos, it supports workflows compliant with ASTM D6667 and D7551.

Stable gas-phase transfer with heated lines

Automatic pressure/temperature control and logging

Safety valves

Analyzer-ready connections and inert-treated tubing

Key Benefits

Safe Vaporization

Low-pressure operation with inlet relief valve for operator safety.

Analyzer-Ready

GC, microGC, GC/MS and elemental analyzer compatibility.

Smart Automation

Automated gas/LPG injections and multi-point calibration with Aiolos.

100% Gas-Phase

Heated transfer lines prevent condensation and carryover.

Flexible Output

Regulated outlet 1–3 bar abs (up to 4 bar); 20–200 cc/min.

Applications

AURA II supports petroleum, environmental and research laboratories — enabling traceable LPG vaporization, analyzer-ready gas-phase transfer and automated calibration with Aiolos.

Oil & Gas — Sulfur

Total sulfur workflows per ASTM D6667/D7551 with Aiolos sequences.

Analyzer Benches

GC/microGC/GC-MS sampling with 100% gas-phase injection and traceability.

Research & Method Dev.

Repeatable LPG vaporization and stable transfer for trace-level studies.

Elemental Analysis

Automated injection and calibration for total sulfur and trace elements.

FAQ — AURA II

Most asked questions about LPG vaporization, analyzer integration and safety.

AURA II safely vaporizes LPG and other liquefied gases into a stable gas phase for precise, traceable analysis on GC, microGC, GC/MS or elemental analyzers.

The line after the vaporizer is heated up to the point of delivery to prevent condensation and carryover, ensuring gas-phase integrity.

AURA II connects to GC, microGC, GC/MS and elemental analyzers. With GasMix™ Aiolos it enables automated injections and multi-point calibration.

Vaporizer 40–160 °C; heated line 120 °C (1 m); outlet pressure 1–3 bara (up to 4 bara); flow 20–200 cc/min; max inlet pressure 50 bara.

Yes. It runs at low operating pressure and includes an inlet relief valve.

Ready to Vaporize with Confidence ?

Bring safe, traceable LPG vaporization to your bench