GASMIX™ PORTABLE

Gas Mixer and Gas Diluter for On-Site Field Calibration - NOMAD

Field-ready GasMix™ mixer/diluter — portable calibrations for analyzers

Built‑in industrial PC & touch — GasMix™ Windows software, projects, sequences, Audit Trail.

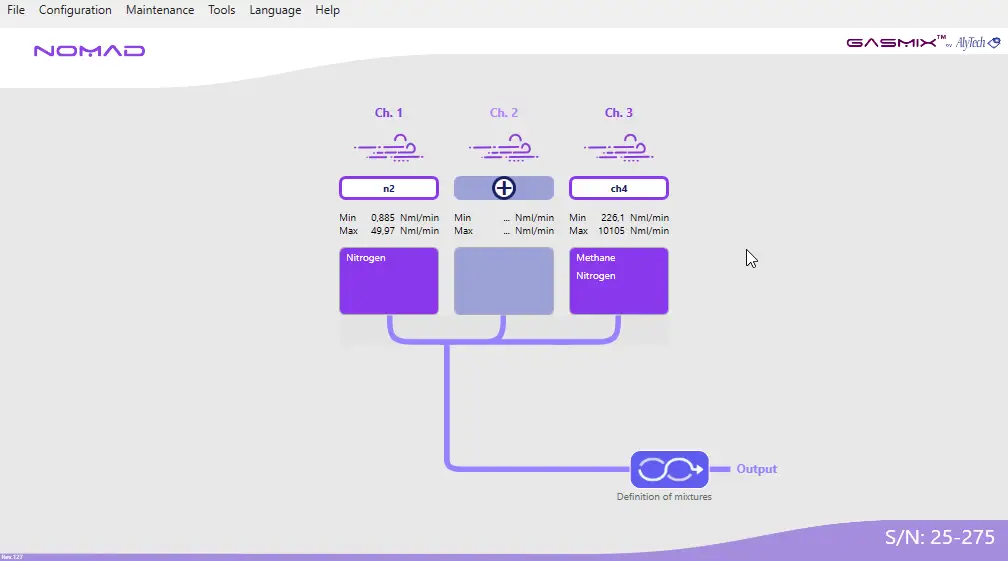

System Concept

NOMAD brings the popular GasMix™ dynamic mixing and dilution technology to the field — for auditors, QA engineers, CEM operators, air monitoring stations and mobile labs. Packaged in a rugged case with a built‑in industrial PC and large touch screen in option, it enables on‑site calibrations and verification of gas analyzers wherever you need them.

Standard gases, sequences and projects are created and stored directly in the GasMix™ software: library of gas standards, multi‑point MFC calibration tables, user profiles, analyzer control parameters and more. NOMAD is compliant with ISO 6145‑7 and provides the same rigorous metrology and traceability as benchtop GasMix systems.

A typical configuration with 4 channels connects two span gases, one interference gas and one dilution gas — delivering full multi‑point span & zero calibrations, linearity and repeatability checks, purity/interference tests and custom sequences.

Operation & Software

NOMAD is operated from its integrated touch PC or an external computer via Ethernet. The GasMix™ application calculates dilution/mixture flows from target concentrations using stored calibration tables, runs user‑programmed sequences, and synchronizes with external analyzers for manual start or fully automatic cycles.

Project‑based workflows

User‑programmed calibration sequences (span/zero, linearity)

Handles pure,concentratedn aggressives gases

Audit Trail

Remote supervision via Ethernet; Windows environment

Metrological Excellence

Every integrated Mass Flow Controller (MFC) undergoes 400‑point factory calibration across the full dynamic range and for each selected gas matrix (He, Ar, CH4, H2, N2, Air, …). This ensures superior linearity and precision, especially at very low and very high flow rates.

NIST-traceable calibration

±1% set point accuracy and <0.1% repeatability *

Automatic K-factor calculation & correction

Automatic uncertainty calculation, full QA/QC traceability with Audit Trail

Certificate delivrance with concentrations & uncertainties

* Valid when all MFCs operate between 10% and 100% of full‑scale flow.

Key Benefits

Portable & Rugged

Rigid case with integrated PC and touch screen for field work.

Accurate & Traceable

±1% SP accuracy, uncertainty reporting and full Audit Trail.

Automated Sequences

Program span/zero, linearity and repeatability checks.

Field Efficiency

Reduce cylinders; on‑site generation cuts logistics and time.

ISO 6145‑7

Proven compliance for calibration and validation routines.

Integrated Control

Windows + Ethernet; local or remote operation.

Applications

Calibration and verification of GC/µGC and gas analyzers in the field; environmental AMS checks; FTIR/RAMAN model building and validation; preparation of customized secondary standards; generation of complex on‑demand mixtures for research.

Environmental AMS

Calibration, repeatability and linearity checks on site.

Mobile Labs

Portable calibrations for GC/µGC and spectrometers.

QA Audits

On‑site verification at customer facilities or stations.

Calibration Labs

Secondary standards and interference/purity tests.

FAQ — NOMAD

Most asked questions about portable GasMix calibrations, automation and metrology.

Typical configurations offer 3 or 4 channels.

Yes. NOMAD workflows comply with ISO 6145‑7. The software provides Audit Trail, roles and reporting.

Dilution up to 1:10,000 with typical flow accuracy ±1% of setpoint.

(When MFCs operate between 10% and 100% of full scale).

Inlet : 3 bar(g) nominal and max 8 bar(g)

Outlet : atmospheric up to 7 bar(g)

It runs on 24V DC using the provided AC adapter. Operation temperature is 10–50 °C.

Ready to Calibrate Anywhere with NOMAD?

Bring GasMix™ accuracy and traceability to the field — portable, automated, analyzer‑ready.