GASMIX™ FLAGSHIP

Gas Mixer and Gas Diluter for High-Flow Industrial - HURRICANE

Versatile platform to generate complex gas mixtures — up to 16 gases

GasMix™ PC software — automatic mixing/dilution, sequences, analyzer sync and full Audit Trail.

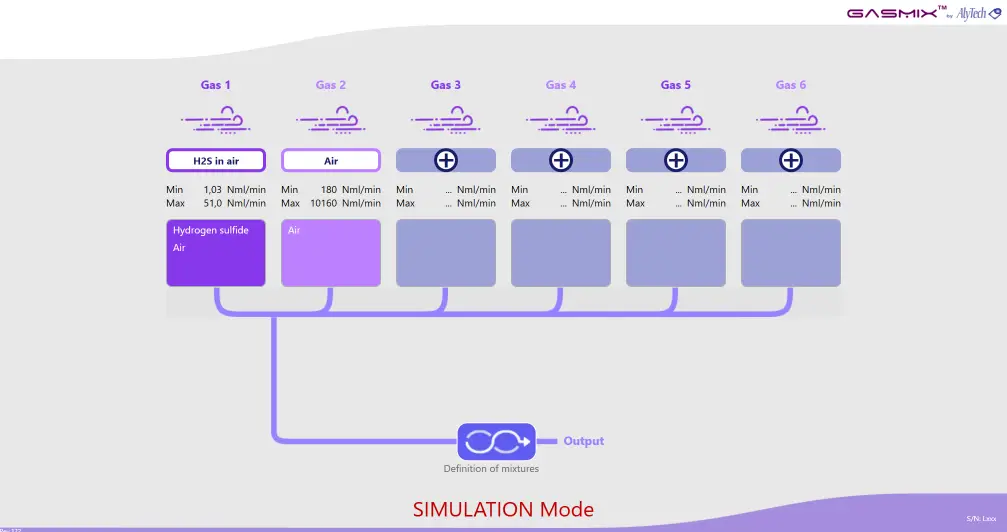

System Concept

HURRICANE is the most powerful instrument in the GasMix™ family — a fully automated gas mixer/diluter engineered to generate highly complex gas mixtures. It blends and dilutes up to 16 gases simultaneously (custom builds up to 20 channels on request), providing accurate, repeatable concentrations from percent down to trace levels.

Designed for advanced laboratories and industrial benches, HURRICANE removes manual calculations: the software computes dilution and span flows from your target concentrations, even for nested, multi‑step recipes. Sequences can be saved, recalled and executed automatically; the system supports remote control and analyzer synchronization, with complete Audit Trail for certificate generation.

By enabling on‑site preparation, the platform reduces the number of cylinders, optimizes gas consumption, helps manage cylinder expiry and significantly cuts operator bench time — enhancing productivity, safety and application flexibility.

Operation & Software

HURRICANE is driven by GasMix™ PC software, providing unified control of channels, flows and pressure conditions. The application calculates mixtures, applies multi‑point MFC calibration curves per gas matrix, and runs programmed dilution/injection sequences with event logging.

Automatic blending/dilution for 6–16 channels

Sequence builder with save/recall for routine procedures

Analyzer synchronization and remote start capability

Audit Trail, users/roles, reporting and export

Options: automated flow regulator, heated tubing, inert version

Metrological Excellence

Every integrated Mass Flow Controller (MFC) undergoes 400‑point factory calibration across the full dynamic range and for each selected gas matrix (He, Ar, CH4, H2, N2, Air, …). This ensures superior linearity and precision, especially at very low and very high flow rates.

NIST‑traceable calibration

±1% set point accuracy and <0.1% repeatability *

Automatic K-factor calculation & correction

Automatic uncertainty calculation, full QA/QC traceability with Audit Trail

Certificate delivrance with concentrations & uncertainties

* Valid when all MFCs operate between 10% and 100% of full‑scale flow.

Key Benefits

Mix the Complex

Up to 16 gases simultaneously; custom builds up to 20 channels.

High throughput

Parallel workflows and automated sequences minimize operator time

Full Automation

Sequence builder, analyzer sync, remote control capability.

Aggressive Gases

SS316 + inert coating, Kalrez® seals; sulfurs, NOx, NH₃, VOC...

Traceable by Design

Audit Trail, users/roles, ISO 6145‑7 documentation and exports.

Scalable & service-friendly

Modular channels, easy maintenance, consistent UI across systems.

Applications

Generation of complex synthetic mixtures; interference testing; development and validation of chemometric models for FTIR, RAMAN and other spectrometers. Typical uses include:

Manufacturing / QA

Sensor test benches: LOD/LOQ and linearity checks; quality control.

Petrochemical / O&G

Calibration of RGA/NGA and GC/µGC methods for complex hydrocarbons.

Automotive

Engine bench tests and emission control development.

Specialty Gases & Research

Customized secondary standards; generation of complex mixtures.

FAQ — HURRICANE

Most asked questions about complex gas mixing, automation and metrology.

Standard configurations support 6–16 channels. Customized systems up to 20 gases are possible on request.

Typical performance is ±1% of setpoint for flow accuracy and <0.1% of setpoint for repeatability, with response time under 5 seconds.

Nominal inlet pressure is 3 bar(g) (max 8 bar(g)). Outlet is atmospheric by default, with higher pressure options on request.

Common options include the FReD automated flow regulator, heated tubing for specific applications, and an inert build compatible with aggressive gases (e.g., sulfurs, H2S, ammonia, VOC).

Yes. HURRICANE complies with ISO 6145‑7. The software provides Audit Trail, user/role management, and certified reporting for traceability.

Ready to Mix It Right with HURRICANE?

Bring automated, traceable complex mixing to your bench — powered by GasMix™.