MIX IT RIGHT

Gas Mixer and Gas Diluter for Industry - GRack

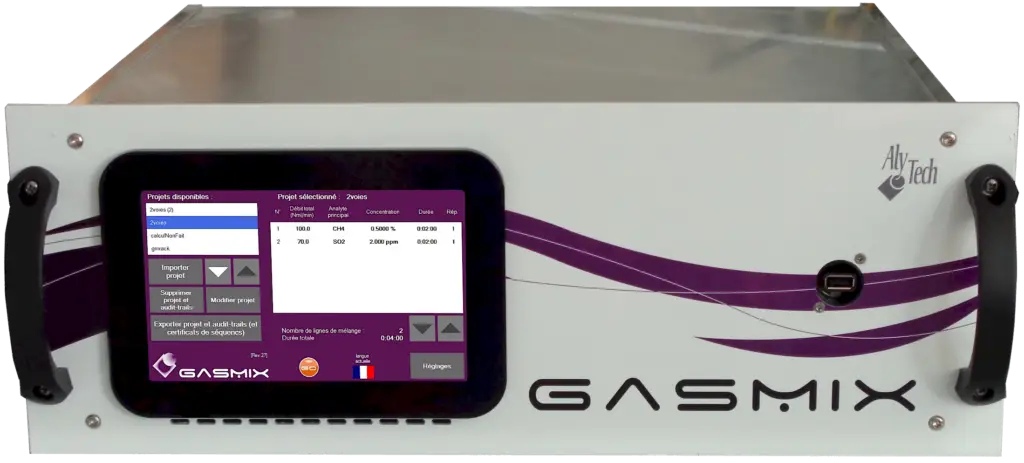

Industrial rack-mounted gas mixing platform

Rack solution powered by AlySoft™ — unified control, recipes, sequences and full Audit Trail.

System Concept

GRack is an industrial, rack-mounted implementation of AlyTech’s GasMix™ architecture, designed for continuous operation and high-throughput laboratories.

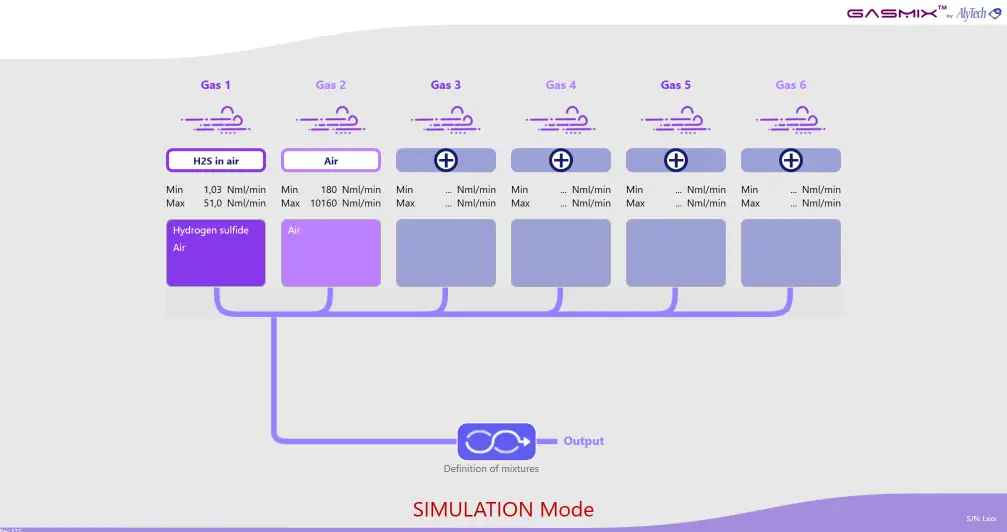

The platform integrates calibrated mass-flow modules, valves and safety functions into a compact 19″ rack, producing on-site calibration mixtures from percent down to trace levels. Modular design lets you scale channels and options while keeping a single control layer.

Powered by AlySoft™, GRack delivers certified traceability (Audit Trail, user management, reports) and repeatable performance for routine QA/QC and production benches.

Operation & Software

Made by experts, GRack is operated via dedicated, intuitive software. The AlySoft™ platform controls every stage of the process — calculating mixtures, applying calibration tables, and running programmed sequences.

User-friendly interface for quick setup

Programmed injection and dilution sequences

Analyzer synchronization (dilution, injection, flushing)

Minimal operator bench time — connect cylinders, launch the sequence, retrieve results

Options: Injection Valve and FReD flow regulator

Metrological Excellence

Every integrated Mass Flow Controller (MFC) undergoes 400-point factory calibration across the full dynamic range and for each selected gas matrix (He, Ar, CH4, H2, N2, Air, …). This ensures superior linearity and precision, especially at very low and very high flow rates.

NIST-traceable calibration

±1% set point accuracy and <0.1% repeatability *

Automatic K-factor calculation & correction

Dilution factor: up to 10,000

Automatic uncertainty calculation, full QA/QC traceability with Audit Trail

Certificate issuance with concentrations & uncertainties

* When MFCs operate between 10% and 100% of full-scale flow.

Key Benefits

Industrial 19″ integration

Robust, serviceable build for production benches and continuous duty.

High throughput

Parallel workflows and automated sequences minimize operator time.

Full automation

Sequences plus analyzer sync minimize operator bench time.

ISO-ready traceability

Audit Trail, user management and certified reports directly from AlySoft™.

From percent to trace

On-site generation of mixtures ranging from high levels down to ppb.

Scalable & service-friendly

Modular channels, easy maintenance, consistent UI across systems.

Applications

GRack suits high-throughput QA/QC labs, analyzer benches and production environments requiring reliable, traceable and automated calibration workflows.

Production QA/QC

Automated calibration routines integrated with benches.

Analyzer Benches

Multipoint sequences, linearity checks, LOD/LOQ.

Environmental & Process

Traceable gas mixtures from percent to trace levels.

Custom Racks

Tailored channel count, valves and safety options.

FAQ — GRack

Most asked questions about rack-mounted GasMix™ systems, OEM integration and metrological performance.

GRack is rack-mounted GasMix™ unit designed for multi-line gas mixing and dilution in fixed installations.

The only difference difference between the 2 is the presence of the touch screen for the GMRack.

The GMRack is the GRack with the touch screen option.

GRack can be configured with several standard gas inlets and one diluent, using multiple Mass Flow Controllers. Typical configurations include 2 to 6 channels, depending on the application and required mixtures.

Yes.

With optional valve manifolds, multiplexers or stream selectors, it can sequentially or simultaneously feed several analyzers or sampling lines, which is ideal for analyzer shelters and automated systems.

From percent to trace or ppb levels, thanks to dynamic dilution and multi-MFC configurations. It supports multi-point calibration, linearity checks, LOD/LOQ studies and automated dilution curves.

Yes.

It is widely used for CEMS calibration and QA/QC routines such as QAL2/QAL3, linearity checks and periodic validation according to EN 14181 and similar standards, when paired with appropriate certified gases.

GRack runs on AlySoft™ (GasMix™ software), providing unified control, advanced sequences, analyzer synchronization, Audit Trail and certificate or report generation. OEM remote integration is also supported.

Yes.

Configurations with SS316, inert passivation and special seals (Kalrez®, Chemraz®) allow safe handling of reactive gases such as H₂S, SO₂, NOx, NH3, VOC and more. Material selection is adapted to the target application.

All MFCs undergo factory calibration with multi-point curves per gas matrix. The software ensures ISO 6145-based dilution, uncertainty calculation, Audit Trail and full traceability from cylinder certificate to final gas mixture at the outlet.

Yes. GRack includes digital I/O (dry contacts / TTL) and optional communication modules, enabling integration into PLC/DCS systems for remote operation, status monitoring and automated test benches.

Routine maintenance includes scheduled MFC recalibration according to your QA/QC plan.

Yes.

The GRack has been used for several years for this purpose by clients such as SGS.

Ready to Mix It Right on site?

Scale your calibration capacity with certified traceability — powered by AlySoft™.