LIQMIX™ INSIDE

Liquid-to-Gas Mixer & Diluter - NEPHOS

Liquid-to-Gas Standard Generator — from % to ppb

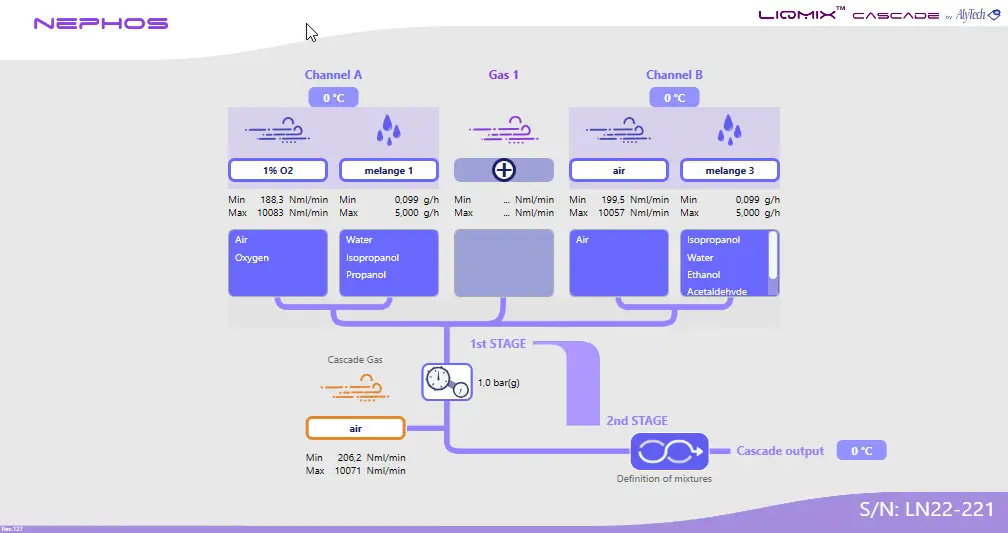

LiqMix™ software — unified control, sequences, analyzer sync and full Audit Trail.

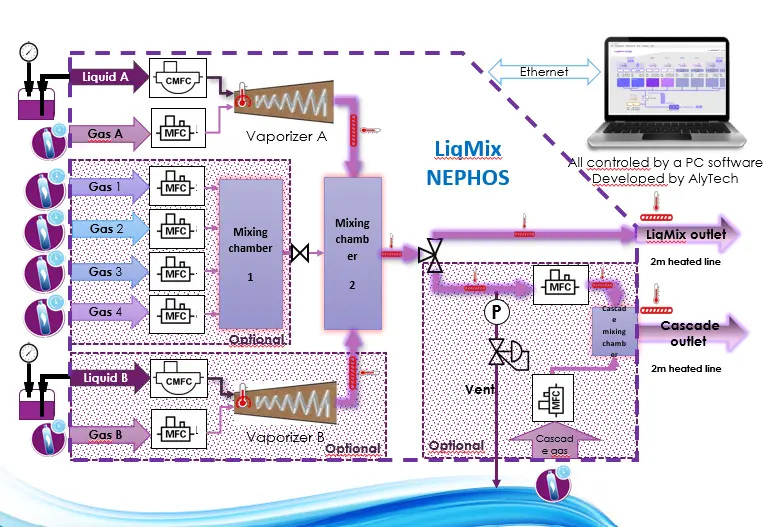

System Concept

NEPHOS is AlyTech’s latest evolution in the LiqMix™ range — a bench solution that produces custom gas standards directly from pure or mixed liquids. Optional cascade dilution unlocks an exceptionally wide concentration span, from percent down to ppb.

The instrument precisely vaporizes up to two liquid phases into a controlled carrier gas stream, generating mixtures on demand with full traceability. A modular architecture lets your system evolve as requirements grow — ideal for QA/QC, method development and analyzer validation.

Heated transfer paths up to the delivery point prevent re-condensation, ensuring a clean, stable gas phase for accurate, repeatable measurements.

Operation & Software

NEPHOS combines a Coriolis-type liquid flow meter with a precisely regulated vaporization chamber. Mass Flow Controllers (MFC/RDM) deliver repeatable dilutions, while heated lines maintain the gas phase to the outlet.

Unified control of liquid and gas flows with LiqMix™ software

User-defined sequences for vaporization, dilution and calibration

Real-time monitoring, safety rules and event logging

Synchronization with GC, spectrometers and gas analyzers

Audit Trail for complete traceability

Metrological Excellence

Every integrated Mass Flow Controller (MFC) undergoes 400-point factory calibration across the full dynamic range and for each selected gas matrix (He, Ar, CH4, H2, N2, Air, CO2…). This ensures superior linearity and precision, especially at very low and very high flow rates.

NIST-traceable calibration

±1% set point accuracy and <0.1% repeatability *

Automatic uncertainty calculation and reporting

Dilution factor: up to 10,000

Automatic uncertainty calculation, full QA/QC traceability with Audit Trail

Certificate delivrance with concentrations & uncertainties

Safety functions and user-defined alarms

* When MFCs operate between 10% and 100% of full-scale flow.

Key Benefits

On-Demand Standards

Create calibration gases from liquids and liquid mixtures, instantly.

% → ppb Coverage

Optional cascade dilution spans wide concentration ranges.

Analyzer Sync

Coordinate sequences with GC, preconcentrators and gas analyzers.

Traceable by Design

Audit Trail, user management and certified reports in LiqMix™.

Stable Gas Phase

Heated lines prevent re-condensation to the point of delivery

Modular & Serviceable

Expand capabilities and maintain easily as needs evolve.

Applications

NEPHOS enables on-demand standards for calibration, validation and research — from volatile organics to humidity and siloxanes.

Biogas & Siloxanes

Generate siloxane standards to assess silicone-related contaminants.

Filter & Sensor Testing

Ethanol/phenol vapors for carbon filter studies; humidity standards for sensor validation.

Trace VOC & Research

BTEX and other VOC mixes for LOD/LOQ, linearity and hysteresis checks.

Aggressive Gases

Inert and aggressive-gas versions with Kalrez, SS316 and inert-coated circuits.

FAQ — NEPHOS

Most asked questions about liquid-to-gas standard generation, traceability and daily operation.

NEPHOS covers a very wide range, from percent-level vapors down to trace and ppb levels. When equipped with optional cascade dilution, the overall dilution factor can reach up to 108, depending on configuration and application.

NEPHOS is suitable for many organic solvents and VOC mixtures (e.g. BTEX, siloxanes, alcohols, phenols) and, in dedicated configurations, water or aqueous solutions. Final compatibility depends on volatility, viscosity and material compatibility; our team can review your liquid list and propose the appropriate configuration.

No, NEPHOS is designed to generate gas standards directly from liquids using a carrier gas. It can also be combined with existing gas standards or GasMix™ platforms when you want to mix liquid-derived components with gas-phase standards in the same stream.

Vaporization takes place in a controlled, heated chamber and the transfer path to the outlet is heated to maintain the gas phase. This minimizes the risk of condensation, especially for higher-boiling components, and improves repeatability at low concentrations.

Yes, on request NEPHOS can be built with inert-grade wetted materials (SS316, inert coatings, Kalrez® seals) for aggressive or reactive compounds. For highly corrosive or unusual chemistries, we recommend providing details so we can check material compatibility and lifetime.

NEPHOS relies on 400-point calibrated MFCs, NIST-traceable references and LiqMix™ software. The software calculates concentrations, manages sequences, logs all critical events in an Audit Trail and can generate certificates including calculated concentrations and uncertainties for QA/QC documentation.

A typical installation requires electrical power, a suitable carrier gas supply (e.g. nitrogen, air or other matrices depending on your application) and proper ventilation or exhaust according to the compounds used. Exact requirements are specified in the technical documentation.

Yes. LiqMix™ can synchronize sequences with GC, preconcentrators, spectrometers and other gas analyzers using digital I/O and timing parameters. This allows fully automated calibration routines with minimal operator intervention.

Ready to Generate Standards on Demand?

Bring traceable liquid-to-gas calibration to your bench — powered by LiqMix™.